Agreed on the 7.62 rounds.

Update:

Box Mag Modification

Before we can do anything to the box, we need to find the flaws in the feeding system.

After investigating, the box mag 'fabic' is the main source of the misfeeding. It is poorly designed in that it is too short. In order to fit the metal grommet, it needed to be placed below the re-enforced webbing. This means that the entire box and fabric need to be raised to prevent the entire weight of the box from resting on the feed tube itself and kinking the spring, jamming the box and putting extreme excess strain on the box motor.

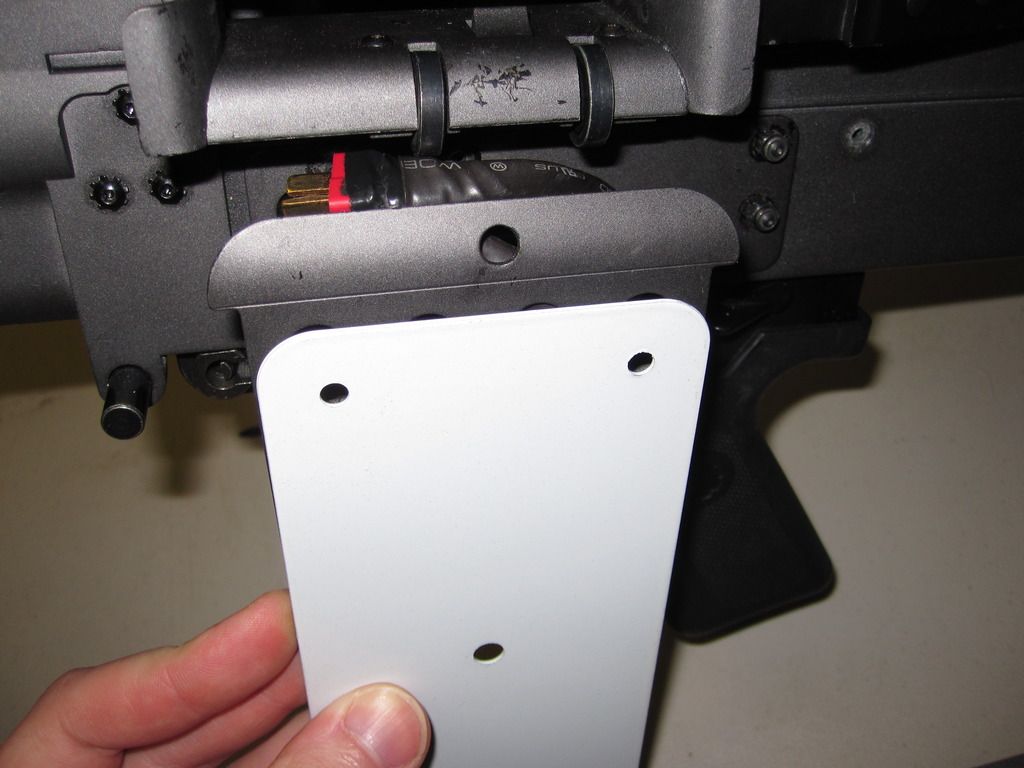

This image shows how the box mag needs to sit to prevent misfeeding and allowing the feed tube flexibility. Notice how the top straps of the box mag are barely touching the rail, and realistically doing nothing. This means there is about a 3/4" travel between where the box SHOULD sit, and where it does sit per A&K's design.

So, how do we fix this?

I chose to modify both the box mag it'self and the fabric box.

I started with a ~1mm thick aluminium cover plate I had laying around that turned out to be the perfect size.

After lining it up, I marked and drilled two 9mm (3/8") holes to fit two 8mm (5/16") bolts. This was followed by two 12mm (1/2") holes to align with the oval openings in the rail. Finally I used a stepped bit to drill a hole to match the large opening for the feed tube.

Then I put it in my vice, and used a hammer to bend the bottom 90 degrees after lining it up as it was too tall overall. This also provides a nice ledge for the plastic box to rest on.

After this I marked and cut two holes in the fabric box for the bolts to pass through and a third hole to bolt the metal bracket to the fabric through an existing 9mm hole in the middle of the bracket.

After this I removed it all and hit it with some Krylon Olive Drab paint.

The final step was to fix the nuts to the box rail on the gun. I first filed all the paint off and left a crosshatch pattern in both the nuts and rail to promote adhesion, then used an industrial adhesive to glue the nuts in place and bolted it down. After I used JB Weld to encase the bolts and allow them to be fixed permanently for easy installation and removal of the fabric box.

After this it was time to modify the box mag to lower the spot where the feed tube exits - the original location is a little too high, hence the weird notch in the box retention rail on the gun. With the box repositioned, it negates this.

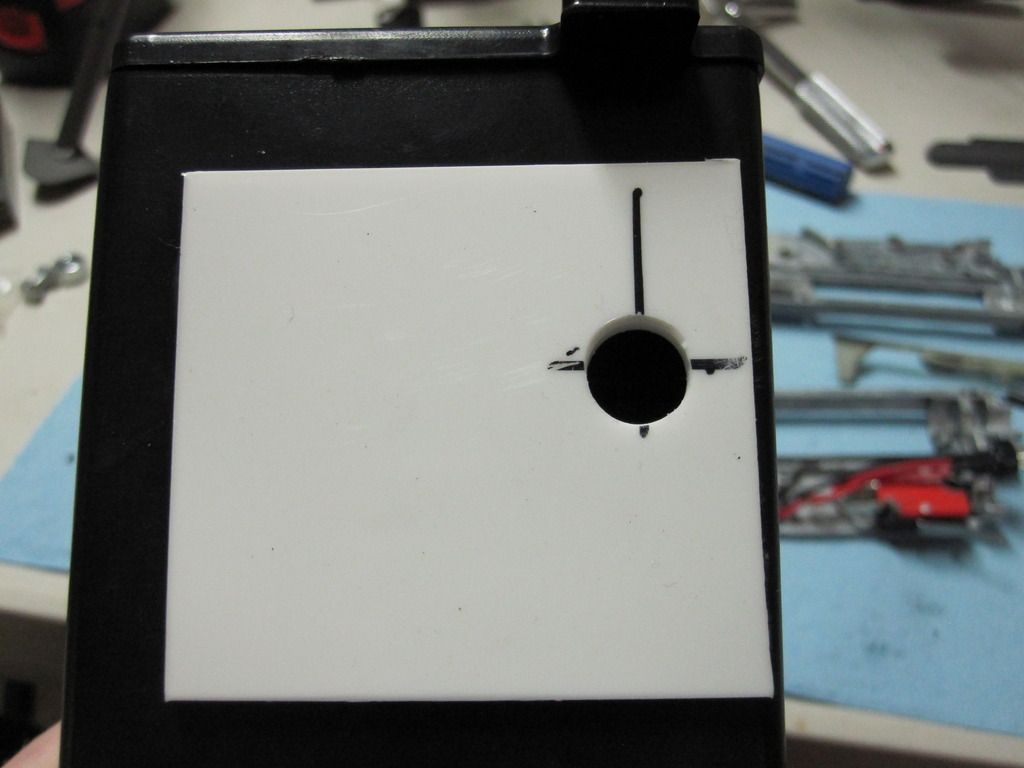

Using a stepped bit I oversized the hole slightly. Then using some 1/8" Lexan I had laying around I cut a small piece and drilled a 3/8" hole to fit the tube. It was then glued in place with super glue, and painted flat black.

I apologise as I did not take a picture with the new hole drilled, but it was about 1/4" farther down. Maybe a little more, 5/16" possibly.

The feed tube now has a nice gentle curve to it while not flexing between the box mag and gun.