|

|

|

#1 |

|

High Torque Gears and Backlash - very intersting find

A buddy of mine put in a set of Modify drop in high torque gears. Afterwards his gun/gears were substancially louder - and sounds like crap in my opinion. Changing motors revealed varying results:

- Old TM motor with lots of pinion wear - quietest (proper sounding) - Stock VFC motor with slight pinion wear - louder (doesn't sound good) - Brand new G&P 160 motor - loudest (haven't heard it myself but I guess it sounds terrible). My conclusion is that there is insufficient backlash in the hi-torgue gearset: Backlash Description: http://www.gearshub.com/gear-backlash.html - google for a better explanation Basically the back of the teeth on the pinion gear hit the backside of the bevel gear teeth (in other words the 'backsides' of the teeth hit each other). Reason: They are torque up gears, therefore you need more teeth on the bevel gear in the same amount of area to create the extra torque - therefore the teeth must be spaced closer together and insufficient backlash was the result. The backlash increased with pinion wear which is why the motors with more wear were quieter. Make sense? So my questions are: - Is this common with torque up gears (ie. are they noisier)? - Is this common only with Modify gears (ie. are they noisier)? I don't believe in using anything but regular ratio gears so I have no experience with hi-torque gear ratios. I'm pretty sure I'm correct in my diagnosis but I'd like to be certain as well as see if other hi-torque gear sets have this problem.

__________________

Ronin 49 Team Member |

|

|

|

|

|

|

#2 |

|

Modify gears are very quiet during operation in my experience. I haven't heard anything about torque up gears being louder or quieter...

I'm not familiar with the backlash issue in AEGs. I think it may be that your motor adjustment screw on the baseplate of the grip needs to be looked at. What type of gearbox is it and what other upgrades are you running?

__________________

Western Arms Infinity 6" Hybrid DX silver Limited Western Arms Infinity 5" Expert KSC MP7A1 KSC USP Match Kimber Warrior [Nova FMU kit] Kimber Gold Combat Stainless [Nova FMU kit]

|

|

|

|

|

|

|

#3 |

|

Lokisama,

Were they regular ratio modify gears? Torque ups? Outside of the gearbox those modify gears turn silky smooth! Definately not a motor height adjustment issue. Even adjusted properly, they were terribly loud (except the worn TM motor/pinion) It's a v2 gearbox (VFC Scar). Can't remember all the upgrades he did but it's a stock TM spring (which shouldn't matter). None of the upgrades should matter as it's clearly a pinion-bevel gear noise issue.

__________________

Ronin 49 Team Member |

|

|

|

|

|

|

#4 |

|

It was a torque up pretty sure. That was installed on a CA reinforced ver3 mechbox.

I think you would have to have the box looked at by a pro gun tech so that he can spot irregular wears and stuff. I think if I had the box in front of me I'd take a look at the tappet plate and the piston itself for any abnormalities. That's just a guess tho. Curious tho, why did you choose the high torque for normal tm spring? Is your battery overpowered for a stock spring by any chance?

__________________

Western Arms Infinity 6" Hybrid DX silver Limited Western Arms Infinity 5" Expert KSC MP7A1 KSC USP Match Kimber Warrior [Nova FMU kit] Kimber Gold Combat Stainless [Nova FMU kit]

Last edited by lokisama; March 26th, 2009 at 23:44.. |

|

|

|

|

|

|

#5 |

|

There a few different pinion gears out there, and the pitch of the teeth is a little different. I've noticed this makes a difference with noise, without the use of torque-up gears.

Case in point: ICS Turbo 2000 motors were whiny, it's an old complaint. The teeth on their pinion were cut very sharp. I had the opportunity to change the pinion out for a Guarder that I picked up from ASCA as few years ago. This new pinion was cut a little less sharp, and the resulting sound was more like an EG700 than the expected whiny ICS motor. This was in an ICS M4 with stock gears.

__________________

Age verifier Northern Alberta Democracy is two wolves and a sheep discussing what's for dinner. Freedom is the wolves limping away while the sheep reloads. Never confuse freedom with democracy. |

|

|

|

|

|

|

#6 |

|

Tys

|

I tried a set of the individual (not caged) Modify torque up gears...without much sucess. Assembling like I would normally...the result was a very "noisy" mechbox. I ran just the gears (no other internals...just the mechbox, shimmed gears, grip and motor) and it was a real racket. Fully assembled and it sounded like the motor height was way off, no matter how I tried to adjust it.

I tried different bushings and even a different mechbox shell...still much noisier than other common gears that I had lying around. I tried several different motors (no ICS ones on hand though), with pinion gears in varying states (from BNIB to quite worn but usable). Same result. Adjusting the motor height did alter the pitch of the screeching...but still unacceptable even at it's quietest. I ended up shimming the whole set so that all three gears were sitting "higher" off the left side of the mechbox. I suspect that this essentially raised the bevel gear and pushed it closer to the right side of the mechbox while maintaining proper shimming/spacing between the gears. So the pinion gear teeth were then able to find their "sweet spot". This seemed to alleviate the noise, at least so it was acceptable. Still one of the noisier sets of gears I've used. Note: I did find that mixing the gears with various other makes was fine and it sounded "normal"...but I kept them together in the end. |

|

|

|

|

|

#7 | ||

|

Quote:

Quote:

Have you seen a regular ratio modify gear set installed? What's your general experience with other brands of torque up gears? After seeing a buddy's systema hi-speed gear set and the tooth profile of the spur gear, I've refused to use anything but regular ratio gears. They've always worked great. I've seen m120 springs pulled easily by mini batteries and if extra ROF is needed/wanted we up the voltage of the battery.

__________________

Ronin 49 Team Member |

|||

|

|

|

|

|

#8 |

|

Tys

|

Sorry, I was beyond frustrated at that point and so I was sort of grabbing gears from my odds&ends gear set box. I suspect that some of them were TM and some of them were CA gears...probably a couple of G&P mixed in. You're really not supposed to do that.

I was guessing that the bevel gear was too close to the centerline of where the pinion gear was coming up from the grip that it wasn't letting the pinion gear engage enough. By shimming the whole set to the right side, the bevel gear would "move over" enough to allow the pinion gear to seat higher in the mechbox and result in more tooth contact. At any rate, that was only 1 set of gears...so far from a general trend. I've mostly stuck to stock gear sets myself. I just bought a set of PP Torque Up gears...but I haven't installed them yet (waiting of a mechbox). I've tried Systema Helical gears...they were ok...but pricey. I've been eyeing a Prom Helical set...but I kind of hope someone buys them before I do...they're really $$. Tys |

|

|

|

|

|

#9 | |

|

Quote:

http://www.elizabethtown.kctcs.edu/m...s/image004.jpg If you picture the teeth as simply smooth surfaces, both bevelled surfaces are parallel with each other always. But you could be right if the bevel angles were different or one of the gears were 'tilted', which could definately be the case with the loose tolerences and QC some of these things have. I'm actually not afraid to mix 'n match gears anymore. I've done it a couple times now with no problems. First one I did was early last season when my buddy's virtually new G&P blew his bevel gear. I swapped it out for a leftover Kraken bevel thinking for sure it wouldn't hold up. He went the whole season with that gear and his gun is still running great.

__________________

Ronin 49 Team Member |

||

|

|

|

|

|

#10 |

|

Tys

|

Gawd it's hard to convey some things over the internet...my failing, no-one elses. I may be totally incorrect and/or may absolutely butcher my explanation of what I'm trying to convey...so feel free to skip right over this one.

Using your picture as a reference.  Assuming that the bevel gear is fixed vertically (by shimming between the mechbox shell) and horizontally (by it's axel), and the pinion gear can move left and right laterally (not exactly for the picture but close enough). If the pinion gear was jammed in to the left of the picture then the teeth would interface, tooth contact would be solid and the gears would probably jam and not rotate well. The amount of the tooth surface of either the pinion gear and the bevel gear would not be the entire surface of each tooth...the tip of the pinion gear teeth would be past the inside edge of the bevel gear. Back it off a bit and you've probably hit a good sweet spot. If the pinion gear was backed off way to the right...tooth to tooth contact would be minimized to the point where it was just the edges touching before they miss each other all together. In the reverse of a jam fit, the widest diameter part of the pinion gear teeth would not make contact and very little of the rest of the tooth would...and I suspect that's why we see so many motors with mangled pinion teeth, but the lower part of the teeth look pristine (sometimes the black oxide coatings aren't even touched). Now imagine your reference picture with the pinion gear still fixed in the same horizontal left right axis. But now the bevel gear is raised up on it's vertical axis. As you described, the two angles are the same between the teeth, but now with the bevel moved up, there's no way the pinion gear can advance far enough to the left to fully engage the teeth of the bevel gear. It's essentially forced to be "backed off". But unlike the previous paragraph, the tooth to tooth contact surface isn't just at it's edges...but rather the teeth are jammed together. If you want to play around with it a bit...with your noisy gear set (no need for anything else in the mech) shim the sector gear and spur gear well and leave the bevel gear kind of loose (not so much that its teeth come off the spur gear teeth or that it rubs on anything) but lose so it can move laterally a bit. Attach the grip/motor, play with the motor height and check it out. You'll notice the bevel gear move side to side relative to the mechbox shell/bushings. Warning - if you power it up and pull the trigger...you may strip your gears doing this...(but I did it anyways!  ) )Anyways...too bad you weren't local. We could pool the parts are try a bunch of stuff out. Tys |

|

|

|

|

|

#11 | |

|

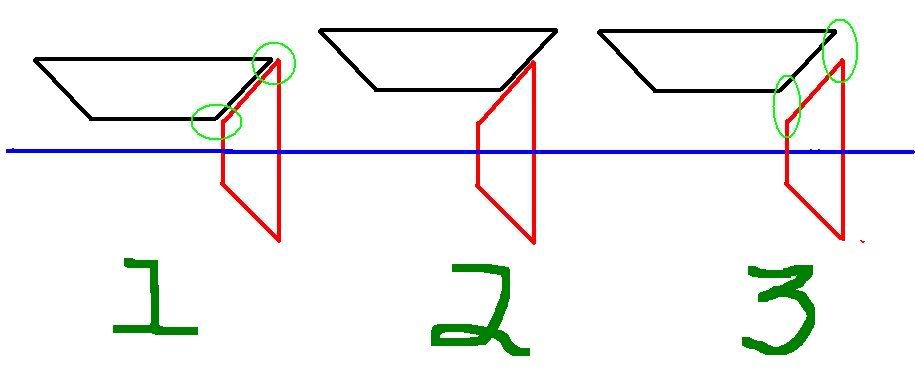

The whole internet discussion thing is brutal to try and descripe things! A picture's worth a thousand words (well maybe not this one):

Quote:

Reference: Black - bevel gear Red - pinion gear Blue Line - axis of motor (to show reference, it shouldn't change unless you run your wires wonky and tilt the motor) Green Circles - just to show that ideally you have the leading/trailing corners lined up for maximum tooth contact Note that the 2 surfaces are ALWAYS parallel to each other (well ideally...my paint skills are terrible!). Tight meshing gears (without jamming things) are nice and quiet ones. They need proper backlash and the same tooth profiles (ideally) to get this. #1 Proper bevel/gear meshing and alignment. Here the bevel gear is shimmed to the right heigh. The leading edge of the pinion is NOT past the inside edge of the bevel. You can see that if you move the pinion from Right to Left the pinion teeth will mesh deeper until the leading edge and inside edge are vertically alined - past this point and then the mechbox will start to jam up (assuming the pinion is cannot move virtically upwards). I usually try to adjust the motor height to get it to jam, then back it off until it sounds nice to get maximum tooth contact. I too have noticed lots of really warn pinion gears with the top 2/3 warn far down and the bottom 1/3 not touched. #2 This is a situation where the bevel is not shimmed and can move in the verticle direction (as you described in your test). You can see that the bevel won't start moving upwards until the leading edge on the pinion moves past the inside edge of the bevel.I don't know why I made this picture??? haha #3 This is the situation where you have shimmed the pinion gear up higher. Now the tooth mesh is crappy, however you increase the backlash. So for properly designed bevel/pinion this would be louder than it should be but can make things quieter for improper ones as it increases the backlash. So, did I just regurgitate most of everything you just said? :banghead: I can't try to shim the bevel higher on my buddy's gun as it is the drop in gearset (caged).

__________________

Ronin 49 Team Member |

||

|

|

|

|

|

#12 |

|

Tys

|

Right...but you flipped the bevel gear orientation from the pic to your #3!

In your #3, lower the bevel gear so it's closer to the C/L of the blue line than in your #1. No matter how deep/shallow you set the motor height, you can't get sufficient tooth to tooth contact. I suspect that's what was happening with my gear set, it was set to "low" (ref. your homemade pics) and needed to be raised. True, at any rate with the caged set I have no idea what do do with them, except put them in the spare parts bin. I was told that you can dismantel that cage and use the gears are loose individual gears. Tys |

|

|

|

|

|

#13 |

|

I have a set of 7mm Modify torque-up gears in a Deepfire 7mm gearbox installed into my custom MP5. The gun is powered by a high torque JG motor (the ones that come with Huang's M120 JG mechboxes and installed into stock JG 416s). It sounds pretty much the same as it did when it had its stock JG mechbox (from when it was a stock JG MP5). The gun is no louder than any of my other guns. Gear noise is minimal and motor noise seems about the same as my JG416, which is not considerably louder than any of my other guns.

That being said, I used to one time have a set of Modify torque up gears in the gun that's now my custom C8. Running a stock TM mechbox shell an EG1000 motor, I noticed that the gun was a lot quieter than running its stock TM gears. So it may be correct that the pinion gear on certain motors mesh with the bevel gear differently.

__________________

|

|

|

|

|

|

|

#14 | |

|

Quote:

__________________

CLICK HERE TO MY WEBSITE Last edited by Tirador; March 27th, 2009 at 15:09.. |

||

|

|

|

|

|

#15 |

|

Aw, okay now I see what you're saying, Tys. That's happened to me only once where the bevel was sitting too low and I had to shim it up higher - I couldn't physically get the motor in the pistol grip and was like WTF? It was actually on my buddy's gun in which I replaced his blown bevel with the kraken bevel. I generally don't put any shims on the bevel gear at all - if I do it's a very small one.

They're my buddy's modify gears and he did all the work himself (I helped troubleshoot a bit). He ran into another really weird probelm with these gears - the axles were thicker than stock. This caused his tappet plate and nozzle not to seat forward enough and cause a big airleak between the nozzle and hopup rubber. He wound up filing the fin back on the tappet. These gears have been a nightmare...oh well, his problem! I told him not too; his stock ones were perfectly fine...dummy. Crunch, thanks for you input. Now everything is clear as mud (like usual) haha. I think I might stay away from the modify gears now with all these inconsistent results. I'm curious if anyone has actually compared the gear diameters of regular/torque/hi-speed gears? The reason I've stayed away from anything but regular ratio gears is because when you change the gear ratio, you change the number of teeth on the gears. To change the number of teeth on a gear you either have to a) change the tooth profile or b) change the diameter of the gear to keep the same tooth profile. Option a) is what I'm assuming happens as there are space limitation inside the mechboxes and I'm sure they compromise in the profile design to get their ratio they require = bad.

__________________

Ronin 49 Team Member |

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|